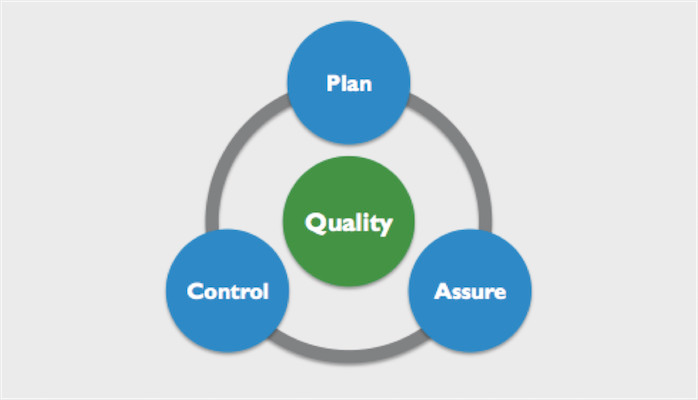

Quality Assurance

FEM Associates has implemented a Quality Assurance system in accordance with ISO 9001. The quality assurance system is based upon a number of documented procedures detailing how each aspect of a project will be undertaken from initial quotation stage through to final delivery and data back-up and storage.

These documents are controlled and issued to relevant members of staff.

Quality Manual

Quality Control Procedures

The quality control procedures detail specific instructions on how each aspect of a project will be undertaken on a technical basis. These procedures provide a clear framework for ensuring that every technical element meets the required standards, outlining step-by-step processes for monitoring and evaluation. By establishing precise guidelines, the procedures help maintain high quality throughout the project’s lifecycle, ensuring consistent adherence to technical specifications. This structured approach not only facilitates effective project execution but also reinforces the company’s commitment to delivering reliable and superior results.

Quality Assurance Procedures

The quality assurance procedures specify in detail the methods employed to meet ISO 9001 requirements at a managerial level. These procedures outline the systematic approaches and practices implemented to ensure compliance with the ISO 9001 standards. By providing a comprehensive framework for adherence, the procedures support effective management oversight and maintain rigorous quality control throughout the organization. This meticulous attention to detail helps guarantee that all managerial processes align with ISO 9001, reinforcing the organization’s commitment to quality excellence and continuous improvement.

Quality Plans

Project-specific quality plans are developed and distributed for all major projects to clearly define project responsibilities, procedures, and schedules. These plans ensure that all relevant staff members are informed of their roles and the detailed processes involved. By controlling and disseminating these plans, the organization ensures that each team member understands the quality standards and expectations, thereby facilitating cohesive project execution and adherence to established guidelines. This structured approach helps maintain high-quality outcomes and effective coordination throughout the project lifecycle.